First impression of Gungnir cermet

Cermet was developed as an alternative to cemented carbides,The word cermet is a combined name. As hard as ceramic and as strong as metal.

Our cermet is TiCN based cermet. Compare with tungsten based cemented carbide, the biggest difference is in the principal component. The main components of cermet are titanium and tantalum/niobium; The main component of cemented carbide is tungsten.

Tungsten has a high affinity with ferrous metals and is prone to chemical reactions. Therefore, when using cemented carbide cutting tools to cut iron metals, due to the large amount of heat generated by cutting will melt the processed materials and stick to the cutting edge of tools, this is what we call “built-up edge”. Once such a built-up edge occurs, the surface to be machined will become rough and difficult to make good cutting.

On the other hand, titanium(Ti) and tantalum(Ta) used in Gungnir cermet are also frequently used in advanced products such as jewelry and watches, which have excellent corrosion resistance and low affinity with ferrous metals. Therefore, when cutting iron materials with cermet cutting tools, it is not easy to produce built-up edges, and the machined surface can become smooth and shiny, meanwhile, cermet cutting tools can also improve the whitish problem on machined surface.

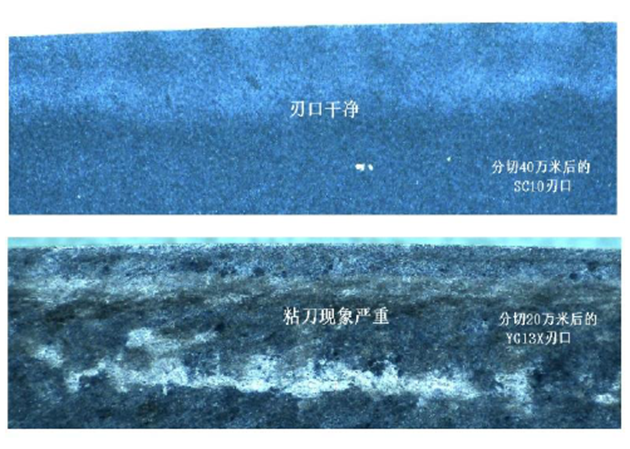

e.g. upper picture shows cermet cutting edge after aluminum cut which was clean and no sticking. Lower picture shows tungsten based cemented carbide cutting edge, which has sticking problem.

Fax :+86 757 8772 2983

Mobile:+86 137 5150 7440

Email: sales@cermet-insert.com

Whatsapp: +86 137 5150 7440